Advanced process control (APC) algorithms

IDR BLOK offers standard and advanced control algorithms.

Standard process control algorithms:

- ON/OFF controller

- P3P controller

- PID controller

- position PID

- velocity PID

- ENTHALPY controller

Advanced process control algorithms:

Modular PID

o PID with additional input and output filters

- Set Point filter

- Manipulative Value filter

o suitable for various control structures (cascade, etc.)

Predictive functional controllers – PFCs

o PFC SF (for first order processes), PFC SS (for second order processes), PFC INT (for integral processes)

o uses a process model to predict and optimize the controller output (MV)

o control quality depends on the accuracy of the estimated process model

o more robust than PID

o easy tuning with Controller Tuning tool

o suitable for high delayed processes

Smith predictor

o PID and a process model with the delay

o most effective for controlling the delayed processes

o efficiency of a feedback control using a Smith predictor increases with increasing delay and the order of the process

Fuzzy logic controller

o block performs the function of fuzzy logic

o Fuzzy Logic Controller Designing Tool – specific user interface for FLC design and testing

o Sugeno 0-order FLC type

o up to 2 inputs, 1 outputs

o triangular membership functions for each input

o most effective for controlling non-linear processes

Fuzzy Gain Scheduling Controller – FGSC

o executes the position PID algorithm with fuzzy scheduling of local controller parameters

o one-dimensional fuzzy scheduling with up to 10 local controllers

o scheduling variable can be PV, SP, MV or measured disturbance

o for high nonlinear processes

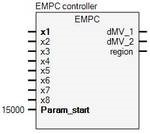

Explicit parametric Model-based Predictive Controller – EMPC

o algorithm for the search of the active region in the state-space partition of the expanded model

o partition should be determined in advance using Matlab software

o up to 8 inputs (state vector x typically formed using Kalman filter) and two outputs (change of MV signal)

o soft and hard limitations on PV can be used

o significantly improve the control of processes which require control very near the process limit or when the process is not allowed to get beyond a certain limit

Please contact us for more information.

SODELUJMO!

Univerzalne rešitve na področju računalniškega vodenja v energetiki in industriji, ki bi ustrezala vsem podjetjem, ni! Ker je naročnik naš partner in ker sodelujemo s podjetji iz različnih panog, razumemo vaše potrebe in znamo izdelati vam prilagojeno rešitev.

Kontaktirajte nas